Standards and certifications in watchmaking were primarily developed for chronometry, as well as to reassure the buyer that their watch had been thoroughly tested to a certain level of accuracy. The standards we see most often in the technical specifications are COSC, METAS, and other company or regional chronometry certifications.

In modern watchmaking, other key standards like the ISO 6425 dive watch standard, which was developed in the 1990s and followed by watch companies, also come into play. These standards were largely based on various military set standards for watches; however, since each military set their own requirements, there was not one universally followed standard. The International Organization for Standardization (ISO) published specific requirements and testing procedures for a watch to be officially designated a “Diver’s watch”.

While there is no ISO standard for pilot’s watches, there are specific requirements set by militaries around the world. One of the most well-known standards is from the WWII German pilot’s watch known as the “Beobachtungsuhren” or “B-Uhren.” B-Uhren pilot’s watch standards are well documented and are still followed by many watch companies to this day.

In March 2012, Sinn lead an initiative in collaboration with the Faculty of Aerospace Technology at the Aachen University of Applied Sciences to create TESTAF – Technical Standard for Pilot Watches. TESTAF was developed so that a pilot’s watch meets all modern-day requirements during flight operations in accordance with visual and instrument flight rules and is qualified for professional use by the pilots.

In the active watch forum days, there were many discussions around this standard. One of the Watchuseek German forum moderators, Dr. Martin Hoch, happened to also be the group leader for creating the TESTAF certification. It was interesting to follow in near real time the developments and ultimately the publishing of the standard. Sinn and Stowa were the only two watch companies that followed and created TESTAF for pilot’s watches. It was anticipated that Laco and possibly Glashütte Original would follow soon after. Glashütte Original at that time still had pilot’s watches (Senator Navigator) in their catalog. One year later, the TESTAF standard would lead to a more comprehensive DIN 8330.

An anecdote worth mentioning about TESTAF is that on one of my visits to Sinn headquarters, I heard the story of Sinn accidentally discovering that their 857 UTC TESTAF had broken a world record. The story goes that Robert Alan Eustace, a senior vice president at Google, wore a Sinn 857 UTC TESTAF watch during his world-record freefall jump from the stratosphere in 2014. The watch was mounted to his pressure suit to withstand the extreme conditions of the jump, including temperatures of -77°C and speeds over 800 miles per hour. Eustace jumped from an altitude of 135,890 feet, breaking the previous record set by the late Felix Baumgartner. The watch is now on display at the National Air and Space Museum. Sinn had no idea about this until they saw it in the news and pictures. This was a genuine test, without a specially engineered watch for the jump or any sponsorship from Sinn.

In 2013, the German Institute for Standardization (DIN), at the request of Sinn, established a working group to develop a new standard for pilot watches based on the TESTAF standard. In addition to Sinn, other members of the group included Aachen University of Applied Sciences and DNV GL (formerly known as Germanischer Lloyd), Lufthansa Cargo, Airbus Helicopters (formerly Eurocopter), Stowa, Laco, and Glashütte Original. DIN is the German national standard that is created if there is not an equivalent ISO standard available for reference.

In March 2016, the DIN 8330 Pilot’s watches standard was announced and published. The DIN 8330-1 and 8330-2 became the successors to TESTAF. The DIN 8330 stipulates that the tests already devised for TESTAF are standardized, precise, systematic, and up to date. It defines the requirements and test criteria for reliable, functional, and safe pilot watches.

It primarily states that in order for a pilot’s watch to be reliable, functional, and safe, it must possess fast, clear readability of the dial both during the day and at night, the ability to operate the watch even while wearing pilot gloves, resistance to temperature changes, impact load, and centrifugal force, as well as accuracy not only at room temperature but also at ranges of between -15°C and +55°C.

DIN 8330-1 expands the range of certifiable watch types, including quartz watches, and introduces more practical requirements for the permitted magnetic signature of a pilot watch. DIN 8330-1 also specifies, systematizes, and updates the regulations that were applied and developed for the TESTAF tests.

In several specific areas, DIN 8330-1 introduces stricter criteria than TESTAF. These areas include readability, resistance to vibration, and resistance to typical aircraft liquids. Additionally, DIN 8330-1 defines requirements for compatibility with night vision equipment for the first time.

One of the objectives of DIN 8330 that I found interesting is that watches conforming to this standard can be recognized by regulatory authorities, manufacturers, and aircraft operators as replacements for malfunctioning on-board instruments. The watch has to meet the appropriate aeronautical specifications comparable to the on-board instruments.

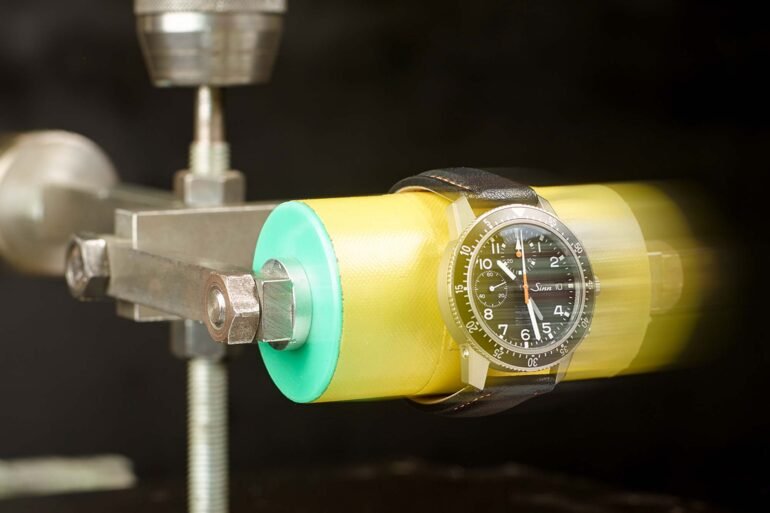

Another DIN 8330 requirement is that the watch should not interfere with the on-board instruments. For example, the pilot’s watch should not affect the on-board magnetic compasses when it is in close proximity. The magnetic signature of a pilot’s watch is measured using a specialized test stand. A magnetic signature can alter existing magnetic fields, potentially causing deflection of an aircraft’s emergency compass if such a watch is used in the cockpit. This includes watches that use a soft iron inner cage. To address this, the test watch is initially demagnetized and then subjected to a standardized magnetic field of defined strength. Then the magnetic signature of the watch is analyzed using the test device. Furthermore, the watch company can add extra protection by using an amagnetic material for the case, such as titanium.

So, who is responsible for testing and issuing the certificate? According to the standard, the actual certification process must be carried out by a neutral institution in accordance with DIN/ISO 17065 and 17067. All DIN 8330 watches are tested and certified by Hamburg-based Seacotec. If the watch passes the tests successfully, it is issued a DIN certificate. Only watches that are issued this certificate can use the DIN 8330 logo on the dial.

When the DIN standard was first published, Sinn introduced three certified models: the 103 Ti IFR, the 103 Ti UTC IFR, and the 857 UTC VFR. However, when I looked for DIN certified watches in Sinn’s current catalog, I was surprised to find none. Knowing how heavily Sinn focuses on engineering and has a laboratory dedicated to testing the criteria stipulated in the DIN 8330, it will not be surprising if Sinn announces a DIN certified watch in the near future.

Stowa also produced DIN certified pilot’s watches under Jorg Schuer’s ownership. The Stowa Flieger DIN Professional was designed by Hartmut Esslinger and features an unusual wavy bezel and coffee pod-shaped crown. Stowa, under its new ownership, is still working on developing its identity and has yet to introduce a DIN certified pilot’s watch.

The most recent watches to receive DIN certification were presented by Laco in 2024 – the Hamburg DIN 8330 and the Hamburg GMT DIN 8330. Most likely, both watches bear the name ‘Hamburg’ since Seacotec is based there. To earn the DIN 8330 certification, both watches underwent 16 rigorous tests designed to evaluate their functional capabilities and endurance under extreme conditions.

These tests included resistance to liquids commonly encountered during flight operations, such as fuels and lubricating fluids, compatibility with cockpit environments and night vision devices. Additionally, the watches were subjected to intense vibrations, shocks, and impacts.

Both watches have 43.5mm diameter cases made from high-grade 904L stainless steel and a dark sandblasted surface that eliminates reflections in the cockpit. They feature a bidirectional rotating ceramic bezel with numerals and indexes coated in Super-LumiNova C1 for enhanced visibility. The bezel features prominent notches and a specialized grip design, allowing for easier operation even when pilots are wearing gloves.

The watches display three large numerals at 3, 6, and 9, a triangle with two dots, white indexes, and hands. To ensure optimal visibility in low-light conditions, the numerals, indexes, and hands are coated with Super-LumiNova C1 luminous material. On the GMT model, the Arabic numerals of the inner 24-hour scale and the tip of the GMT hand are coated with Super-LumiNova in Dark Orange.

The Hamburg DIN 8330 and the Hamburg GMT DIN 8330 have a retail price of $2,170 and $2,890, respectively. Each watch comes with a DIN 8330 certificate.

For the German watchmaking industry, the new standard for pilot watches provides major motivation to maintain a leading role and credibility in the pilot’s watches segment. For watch enthusiasts, enhanced functionality and durability offer a justification to buy DIN 8330 certified watches, just like COSC certification or ISO 6425 compliance. Naturally, marketing and salespeople do not miss a good opportunity to exploit the benefits of certification and justify higher prices. However, the overall impact of DIN 8330 is a positive one, and it could potentially become an internationally observed ISO Pilot’s watch standard.

Bhanu Chopra

2025-10-03 19:00:00